Heat Press

Our Heat Press department is home to 3 different decoration techniques; sublimation, vinyl applique and digital transfer. Each technique offers a different look and feel but all are pressed, or transferred, to garments via heat and pressure.

heat press process

Vinyl Colors

STANDARD VINYL COLORS

PREMIUM VINYL

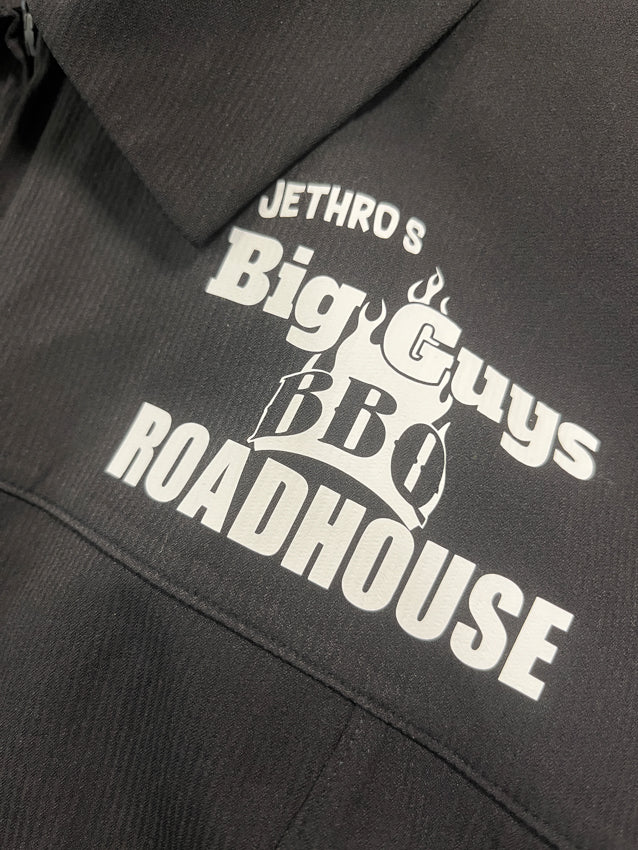

heat press gallery